#makeovermonday - How to restore a Mercedes-Benz 280 SL Pagoda?

The appearance of a perfectly restored pagoda triggers pure happiness in classic car enthusiasts. It is not uncommon for this exhilaration to be followed by enthusiasm for the impeccable restoration works. “Paint, leather and chrome parts have undoubtedly been restored here” - but is that really all? We look forward to giving you an insight into our classic car manufactury and professional restoration. A look behind the scenes, at the craft of the passionate and experienced automobile lovers of our Arthur Bechtel Classic Motors Manufactory team: this is what awaits you in our #makeovermonday series.

Part 1 - The undressing

Classic car dismantling & painting

The base

The journey of a Mercedes-Benz 280 SL Pagoda often begins in an abandoned back yard or a dusty shed. Over the years we have learned that owners often have no concrete idea of what treasures they are storing in. But the awareness of maintaining and increasing value of Mercedes-Benz classic cars has been coming more and more for some time now, to the delight of current and future owners.

When it comes to our restoration project, our basis models, we are uncompromising. In addition to the quantity - i.e. the number of items produced at the time - the decisive criteria are originality and quality. The aim is to present a perfectly restored piece without, however, affecting the historical character of the vehicle. All efforts are aimed at preserving the greatest possible authenticity of the classic car during the restoration.

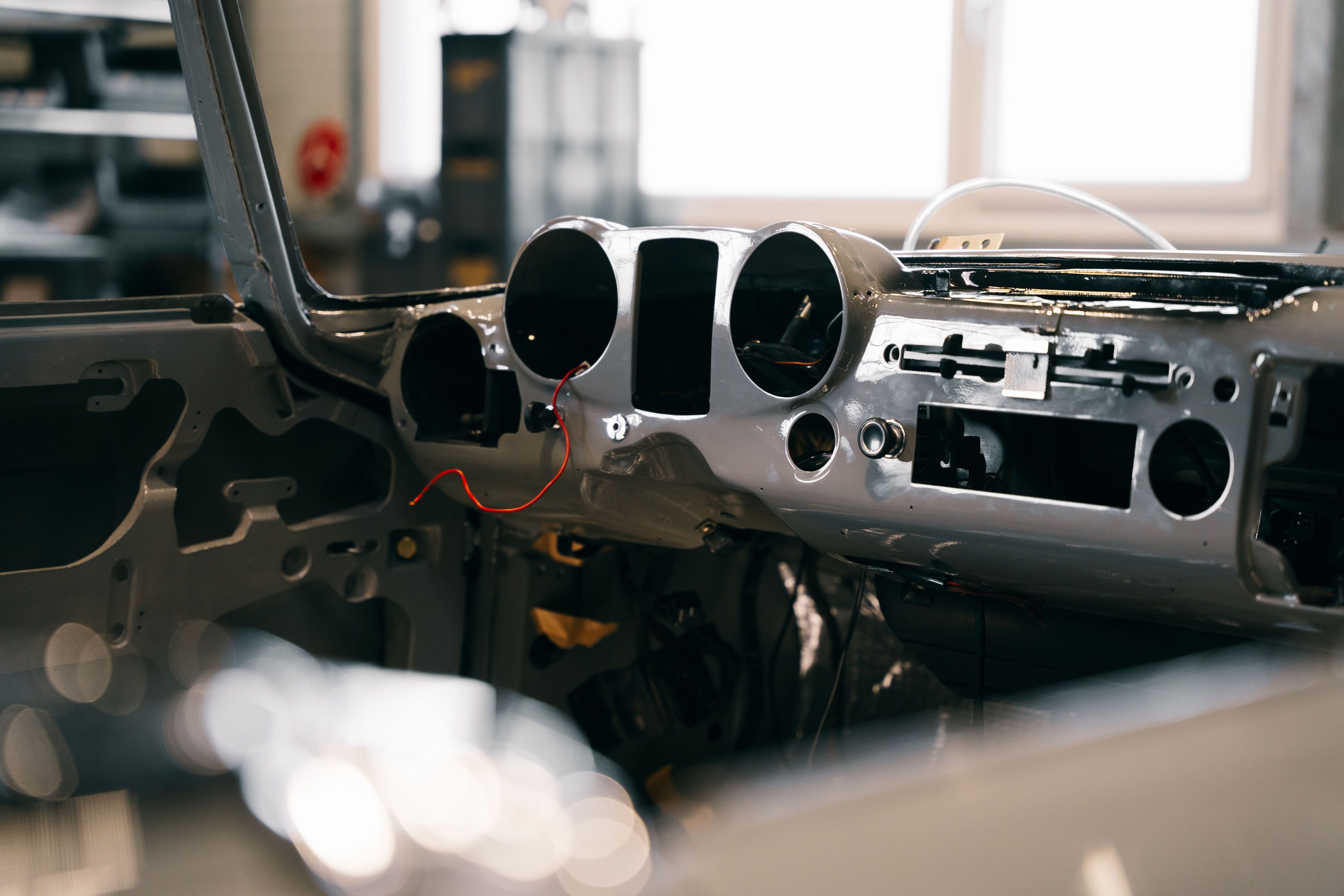

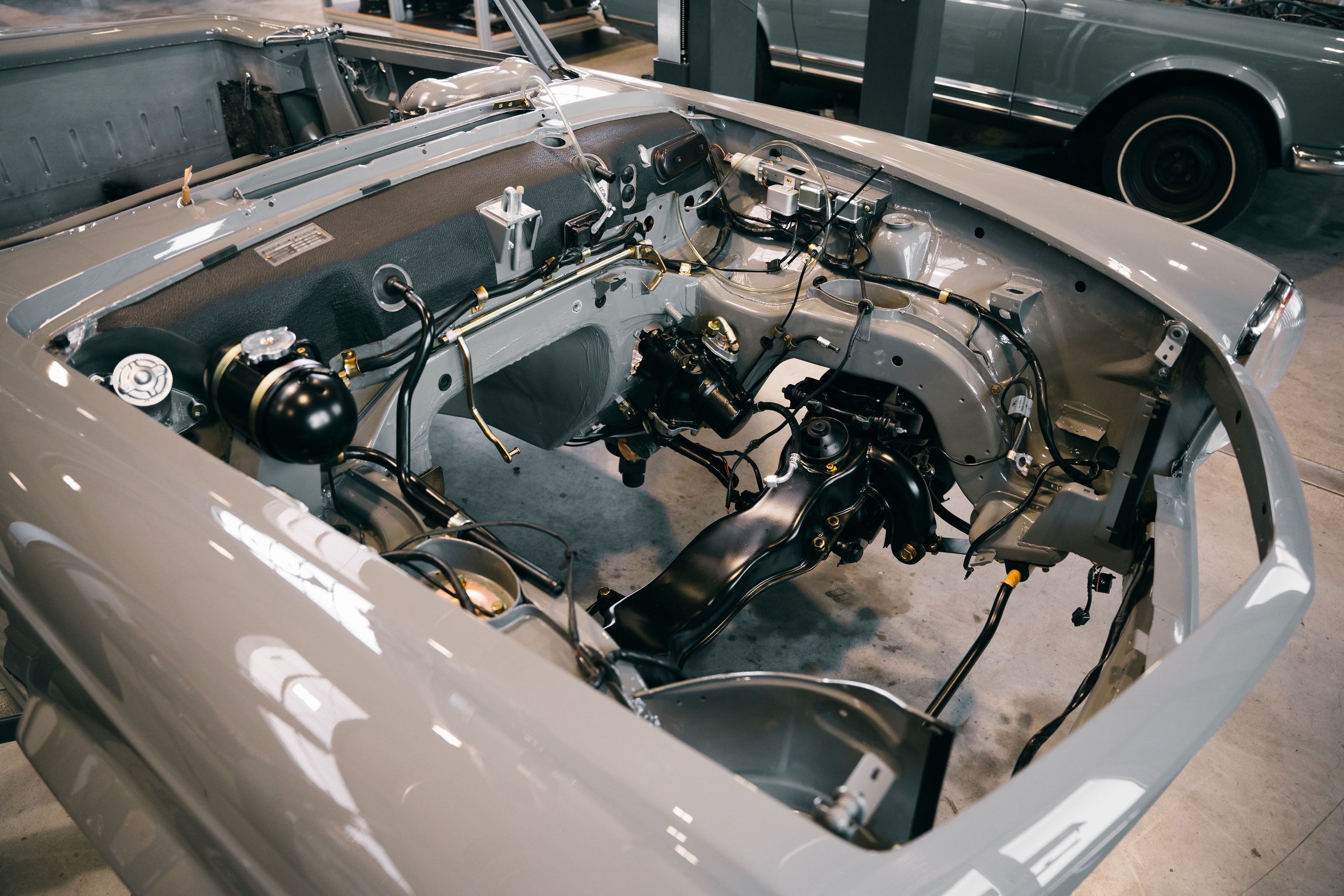

The dismantling

After selecting the basic model the classic car is professionally dismantled. All parts are evaluated: is it possible to restore? Does the part have to be renewed? Using our test sheets, we meticulously document the vehicle on paper. In addition, we photograph every step.

Paint preparation and paint on a classic car

1 surface preparation

Blasting the steel part

All steel parts are blasted. This step is imperative to remove dirt, rust, outdated layers of paint and silicone.

Chemical paint stripping

The aluminum parts are chemically stripped to remove stubborn layers of paint, even in any cavities, without leaving any residue. Dip paint stripping has the advantage over abrasive paint stripping (e.g. sandblasting, which is used on steel parts) that it is much gentler and more thorough.

2 composition

The body is professionally reconditioned: all gaps and moldings are adjusted.

3 primer

Primer coat

Cathodic dip painting: In the last step of the paint preparation the body is being immersed in a bath of desalinated water, binders, color pigments and organic solvents. Here the body acts as a cathode, it attracts the pigments in the solution in a uniform layer thickness over the entire surface. The drying takes place at high temperatures. With a Cathodic dip painting:, permanent corrosion protection is offered right into the narrowest cavities.

4 filler, base coat and clear top coat

The filler is applied to the body in order to level out the unevenness of the surface and to prepare the body optimally for the basecoat. The first layer, visible to the vehicle owner, is applied. This basecoat contains the color and effect pigments (metallic paints) and forms the coloring layer. This layer is usually the thinnest layer. The final layer, the clear top coat, is intended to protect the base coat and give it a refining high-gloss effect. The flexible, impact and chemical resistant coating also has a UV filter that protects the basecoat from fading.

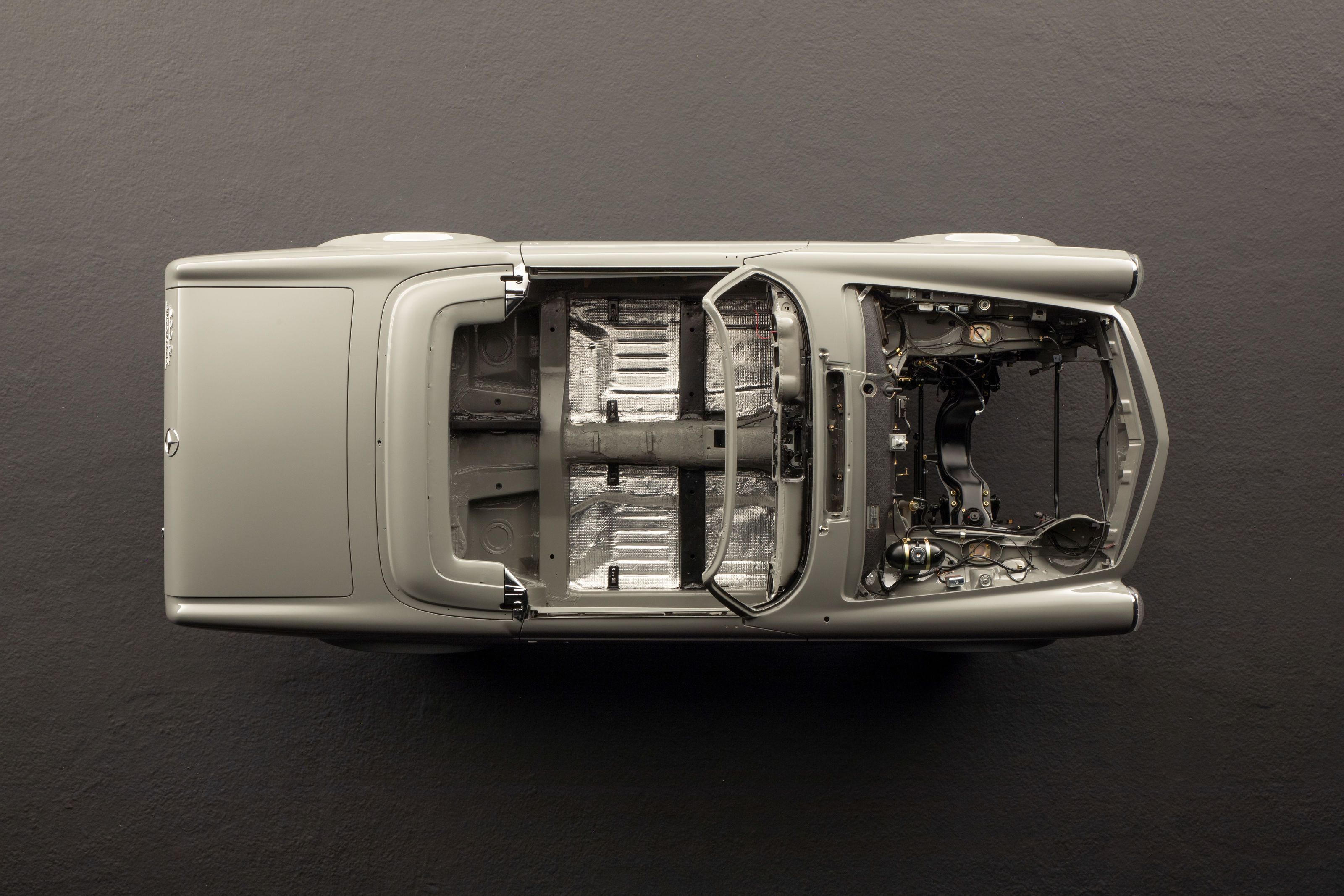

Preliminary result

We have come to a point where you can already guess how the end result will look like. Are you interested in what happens next? We look forward to present you the next intermediate step of the restoration next week (on August 30th, 2021). Stay tuned for an insight into the works of the "inner life" of a Mercedes-Benz 280 SL Pagoda: in our series #makeovermonday.

Follow us on

Instagram: @arthurbechtelclassicmotors